Overview

Materials Processing and Characterization Group

The Materials Processing and Characterization Group takes advantage of a multidisciplinary approach that integrates materials science, plasma physics, and nuclear technology. The Group enfasis is on developing and understanding of advanced materials capable of withstanding extreme environments, such as high temperatures and intense radiation typical of nuclear fusion reactors and hydrogen storage systems.

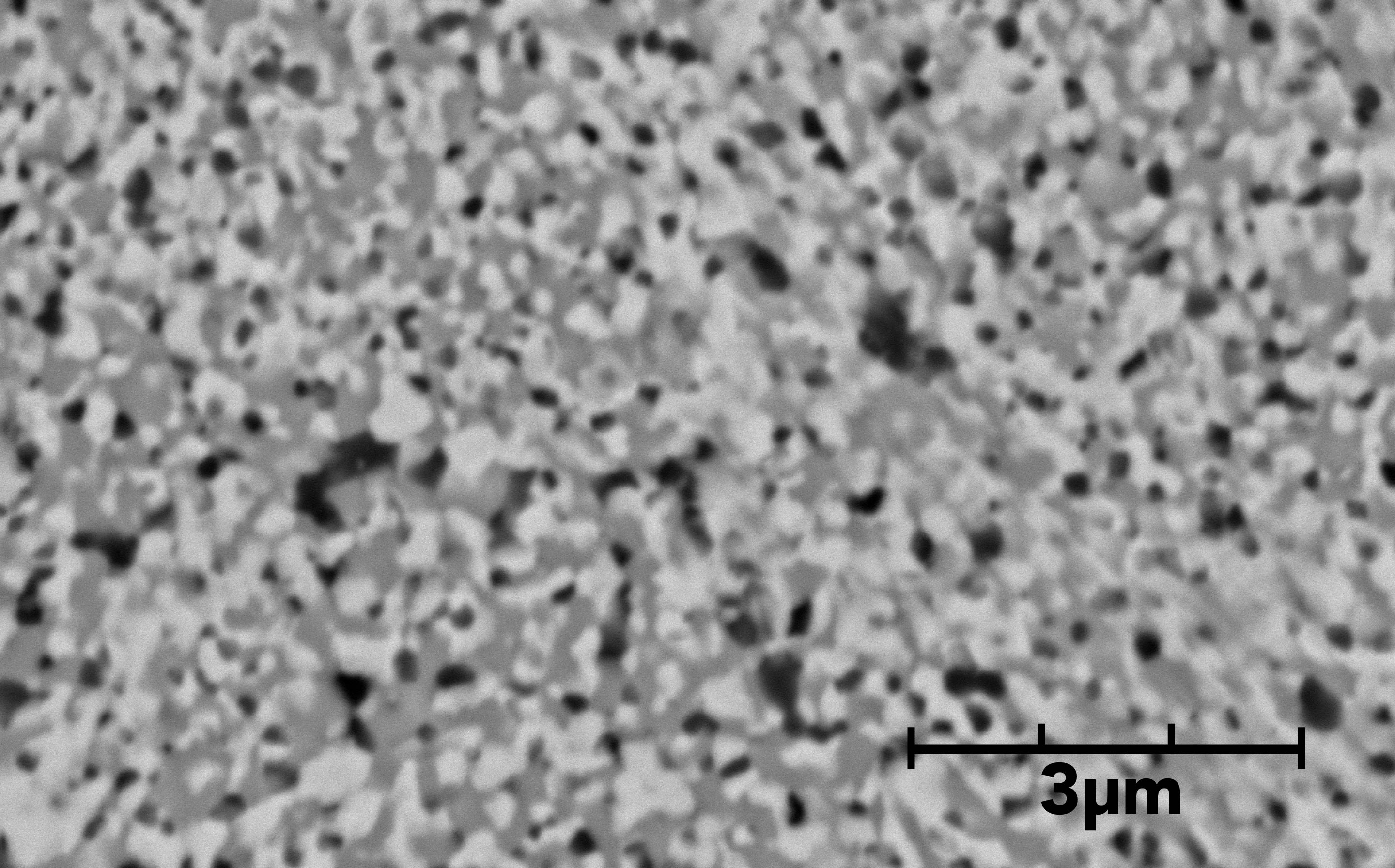

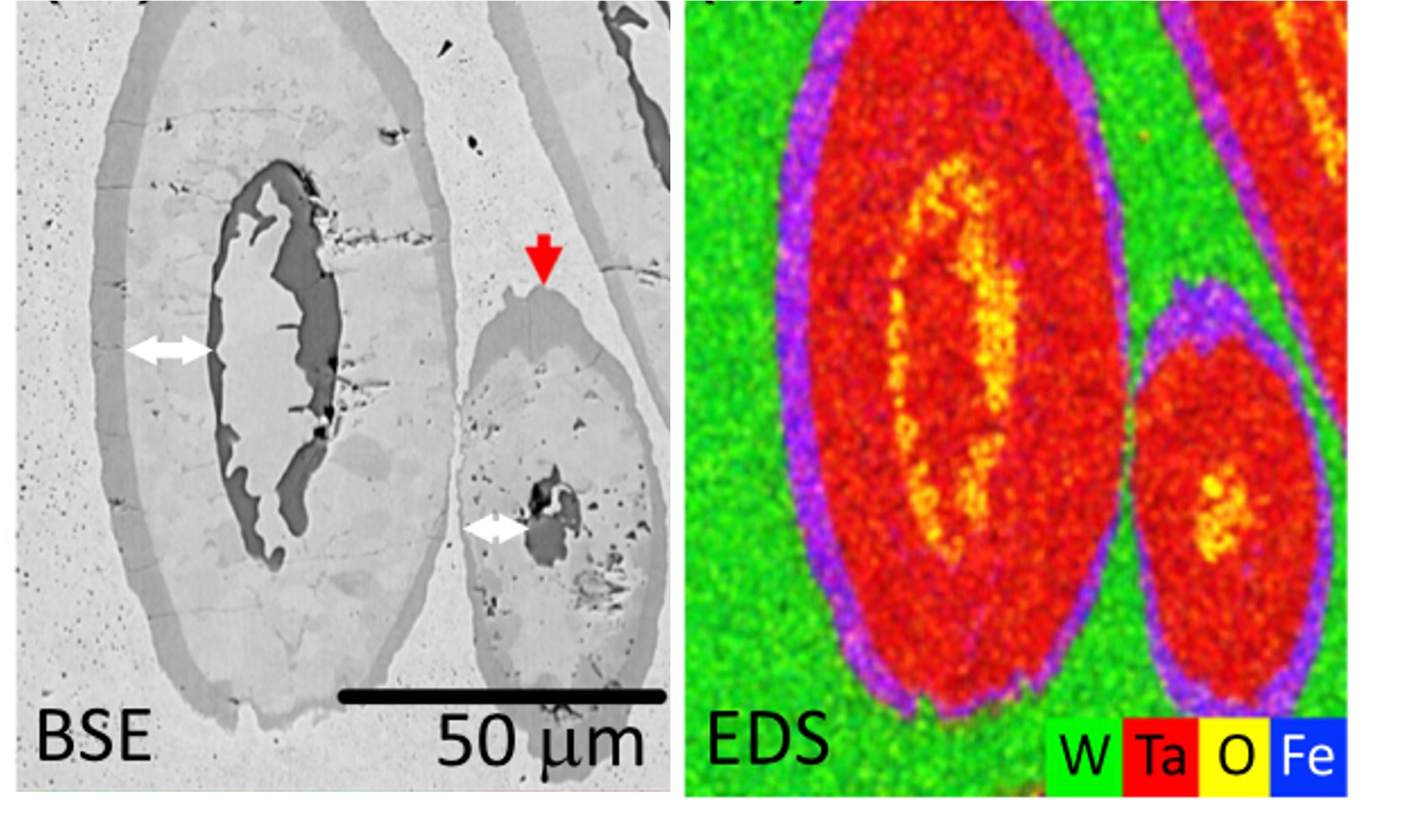

At the core of this research is a merging between materials processing techniques, such as mechanical alloying, sintering and composite fabrication and ion beam characterization methods. This synergy allows the group to design and produce innovative materials, but also to directly assess their performance under reactor relevant conditions.

Recent developments in materials processing include high entropy alloys (based on W), composites (W-Ta fibre) and cermet (WC-Cu).

At the same time, materials are evaluated using experimental setups that simulate plasma-material interactions, including studies of real reactor components retrieved from JET, WEST or COMPASS. The insights gained from Ion-Beam Analysis (IBA) and new measurements of stopping power and cross-sections help validate theoretical models and refine material design, ensuring long-term performance and safety in fusion applications.

This interconnected research strategy has led to significant contributions, such as confirming low fuel retention and dust production, key aspects for ITER operation, resulting in the publication of over 100 peer-reviewed papers. The group's collaborative approach ensures that material innovation is always guided by real-world application and operational input.

Materials development and Plasma Wall Interaction studies

Development of new materials for fusion applications and study of their erosion and retention properties;

Development of new alloys to study the influence of their thermodynamic parameters in hydrogen applications;

Study erosion/deposition and retention properties in the ITER-Like Wall in JET;

Properties of WBS and insulating materials by ion irradiation

Study the effect of ion irradiation on the properties of WBS hetero- and nanostructures;

Doping and tailoring the electrical and optical properties of nanostructures by irradiation to enhance sensing efficiency;

Fostering the potential of ion implantation and irradiation to process advanced WBS structures for light emitters and sensors;